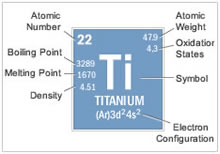

Classification

The respective application of different grades of titanium alloys

Submitted by admin on 07/27/2016

Each titanium alloy has its own purpose. We have a very clear understanding for the using of titanium alloy in aircraft manufacturing and aerospace industry, there are also a lot of uses of titanium alloy in the social life and the machinery industry, such as glasses frame, golf clubs, super sports bike, and so on. But we know little about the use of titanium alloy in the army and the Navy. In the following, I will list the application of some high performance titanium alloy in the defense industry.

1.The engine industry

Titanium 5Al2.5Sn, high strength titanium alloy, used as gear sleeve, engine casing, blade cover.

Titanium 8Al1Mo1V, high temperature titanium alloy used as engine blade, gyro guide cover etc.

Ti 6Al4V (tensile strength not less than 895MPa), heat treatment of titanium alloy, used as core machine blade and impeller.

2.The aviation industry

Titanium 6Al2Sn, reinforced titanium alloy, used as fasteners, guiding device, important structure.

Titanium 4AlMo1V titanium alloy is used as aircraft frame.

Titanium Sn5Zr1Mo, titanium alloy used as landing gear, aircraft bearing rack, fastener.

3.Aerospace Industry

Titanium alloy 1M1315 is used as rocket panel, missile base member.

Titanium alloy 1M1550 is used as missile power blade sleeve.

Titanium alloy T-A6V - the main material used in the spacecraft.

4.Land force

Titanium A7D - Mechanical analysis of a new type of armored vehicle.

Ti A6Z5W - anti tank rocket (missile), missile cover components.

Titanium 1M1551 - fire high speed rotating parts of a certain armored vehicle.

5.Navy industry

LT41 titanium alloy - ship large area skin.

3.7114 titanium alloy - excellent solderability, good formability for watertight compartment.

V13CA titanium alloy- honeycomb ship, bearing frame.

1.The engine industry

Titanium 5Al2.5Sn, high strength titanium alloy, used as gear sleeve, engine casing, blade cover.

Titanium 8Al1Mo1V, high temperature titanium alloy used as engine blade, gyro guide cover etc.

Ti 6Al4V (tensile strength not less than 895MPa), heat treatment of titanium alloy, used as core machine blade and impeller.

2.The aviation industry

Titanium 6Al2Sn, reinforced titanium alloy, used as fasteners, guiding device, important structure.

Titanium 4AlMo1V titanium alloy is used as aircraft frame.

Titanium Sn5Zr1Mo, titanium alloy used as landing gear, aircraft bearing rack, fastener.

3.Aerospace Industry

Titanium alloy 1M1315 is used as rocket panel, missile base member.

Titanium alloy 1M1550 is used as missile power blade sleeve.

Titanium alloy T-A6V - the main material used in the spacecraft.

4.Land force

Titanium A7D - Mechanical analysis of a new type of armored vehicle.

Ti A6Z5W - anti tank rocket (missile), missile cover components.

Titanium 1M1551 - fire high speed rotating parts of a certain armored vehicle.

5.Navy industry

LT41 titanium alloy - ship large area skin.

3.7114 titanium alloy - excellent solderability, good formability for watertight compartment.

V13CA titanium alloy- honeycomb ship, bearing frame.

------分隔线----------------------------