Classification

The properties of titanium alloys

Submitted by admin on 07/22/2016

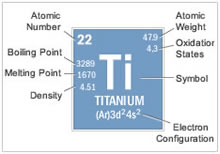

Titanium alloys are widely used in aerospace and other fields because of its low density, high specific strength, high temperature resistance, good oxidation resistance and so on. But the mechanical processing performance of titanium alloy is poor, which affects the widespread use of the material.

Titanium alloy is added to alloy element in the industrial pure titanium to improve the strength of titanium. Titanium alloy can be divided into three types: a titanium alloy, b titanium alloy and a+b titanium alloy. A+b titanium alloy is composed of a and B dual phase, this kind of alloy has stable structure, better high temperature deformation properties, toughness and plasticity, which can carry on quenching and aging treatment to make the alloy strengthen. The performance characteristics of titanium alloys are mainly:

1.High specific strength: Titanium alloy has low density (4.4kg/dm3) and light weight, but its specific strength is larger than that of ultra-high strength steel.

2.Heat intensity is high: The thermal stability of titanium alloy is good, at 300 ~ 500 degrees, its strength is 10 times higher than that of aluminum alloy.

3.Large chemical activity: Titanium has strong chemical reaction with oxygen, nitrogen, carbon monoxide, water vapor and other substances in air to produce TiC and TiN hardening layer on the surface.

4.Poor thermal conductivity: Titanium alloy has poor thermal conductivity, at 200 degrees, the thermal conductivity of titanium alloy TC4 is l=16.8W/m / ℃, the thermal conductivity coefficient is 0.036 cards / m / ℃.

Titanium alloy is added to alloy element in the industrial pure titanium to improve the strength of titanium. Titanium alloy can be divided into three types: a titanium alloy, b titanium alloy and a+b titanium alloy. A+b titanium alloy is composed of a and B dual phase, this kind of alloy has stable structure, better high temperature deformation properties, toughness and plasticity, which can carry on quenching and aging treatment to make the alloy strengthen. The performance characteristics of titanium alloys are mainly:

1.High specific strength: Titanium alloy has low density (4.4kg/dm3) and light weight, but its specific strength is larger than that of ultra-high strength steel.

2.Heat intensity is high: The thermal stability of titanium alloy is good, at 300 ~ 500 degrees, its strength is 10 times higher than that of aluminum alloy.

3.Large chemical activity: Titanium has strong chemical reaction with oxygen, nitrogen, carbon monoxide, water vapor and other substances in air to produce TiC and TiN hardening layer on the surface.

4.Poor thermal conductivity: Titanium alloy has poor thermal conductivity, at 200 degrees, the thermal conductivity of titanium alloy TC4 is l=16.8W/m / ℃, the thermal conductivity coefficient is 0.036 cards / m / ℃.

------分隔线----------------------------