Classification

Seam Welded Titanium Tubes

Submitted by admin on 12/12/2013

Manufacturing process of seam welded titanium tube are as followings:

Seam welded titanium tube has such features: seam welded titanium tube adopts inert gases to effectively protect the welding areas. Producers use TIG welding technology to make seam welded titanium tubes.

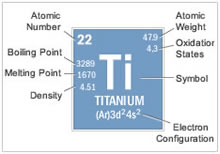

Since titanium has specific physical and chemical characteristics, so there are great differences in the welding technology of titanium and other metals.

When welding titanium tube, producers must make sure that:

(1) In welding area, titanium would not be contaminated by the active gas at 250 ℃, like N, 0, H and impurity elements C, Fe, Mn.

(2) Titanium could not form coarse grain structure.

(3) Do not produce greater welding residual stress and residual deformation. Therefore, manufacturers need carry out strict quality control of whole process according to the reasonable technology and accordance with quality management standards.

2. Requirements to welding materials are as followings:

(1) The chemical composition and mechanical properties of wire for welding should be similar with that of seam welded titanium tube.

(2)If the seam welded titanium tube is called for high plasticity, wire for welding with higher purity than that of seam welded titanium tube should be used.

Before using wire for welding, producers need to reinspect the wire. Make sure that the surface of wire for welding should be clean, no oxidation, no cracks, no expansion scab scale, no scar and other defects.

Titanium manufacturer-Zhengzhou Sanhui Co., Ltd offers wide range of titanium products with reliable quality. We are one Alibaba 10 years’ golden supplier.

Seam welded titanium tube has such features: seam welded titanium tube adopts inert gases to effectively protect the welding areas. Producers use TIG welding technology to make seam welded titanium tubes.

Since titanium has specific physical and chemical characteristics, so there are great differences in the welding technology of titanium and other metals.

When welding titanium tube, producers must make sure that:

(1) In welding area, titanium would not be contaminated by the active gas at 250 ℃, like N, 0, H and impurity elements C, Fe, Mn.

(2) Titanium could not form coarse grain structure.

(3) Do not produce greater welding residual stress and residual deformation. Therefore, manufacturers need carry out strict quality control of whole process according to the reasonable technology and accordance with quality management standards.

2. Requirements to welding materials are as followings:

(1) The chemical composition and mechanical properties of wire for welding should be similar with that of seam welded titanium tube.

(2)If the seam welded titanium tube is called for high plasticity, wire for welding with higher purity than that of seam welded titanium tube should be used.

Before using wire for welding, producers need to reinspect the wire. Make sure that the surface of wire for welding should be clean, no oxidation, no cracks, no expansion scab scale, no scar and other defects.

Titanium manufacturer-Zhengzhou Sanhui Co., Ltd offers wide range of titanium products with reliable quality. We are one Alibaba 10 years’ golden supplier.

------分隔线----------------------------