Classification

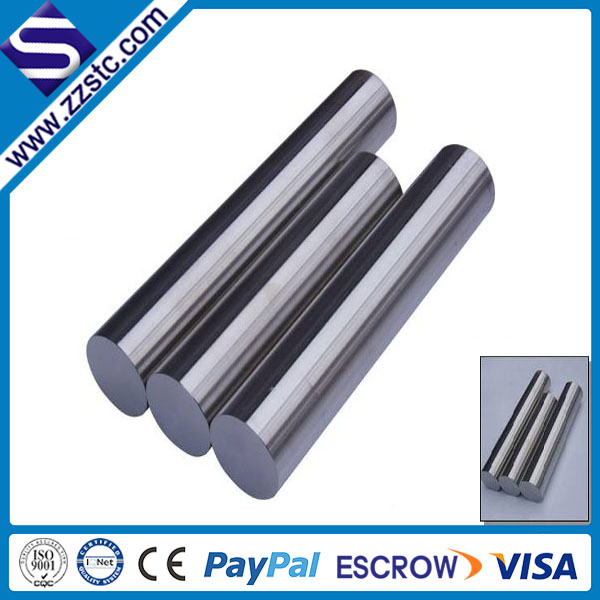

Titanium bar

Submitted by admin on 09/15/2015

1. The usage of titanium bar: titanium bar is mainly used in machinery equipment, anti-corrosion equipment, electroplating equipment, chemical, petroleum, coking and zinc manufacturing equipment and the mixing shaft. Titanium bar is also used in medicine and precision processing.

2. The classification of titanium bar: the classifications of material for titanium alloy have grade TC4, TA9, TA10, TA18 and TC21. The classifications of shape have titanium round bar, titanium square rod, titanium square bar and titanium black bar.

3. The processing method of titanium bar: Hot rolled titanium bar. Hot extruded titanium bar. Hot forging titanium bar. All adopt the methods of scaling and polishing to process it into finished production.

4. The application of titanium bar: According to titanium bar’s characteristics of corrosion resistance, wear resistance, high temperature and no magnetic, etc. It is usually used as the main parts of the equipment, such as shaft, fasteners and stirring shaft, etc. Due to its non-toxic and non polluting characteristics, titanium bar is made into filter element and has a wide range of applications. In addition, titanium bars also have other characteristics such as high strength, good toughness, low elastic modulus and biocompatibility with human beings, which are widely used in medical industry.

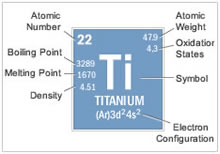

5. Tensile strength of pure titanium: 250-320MPa. Tensile strength of titanium alloy: 890MPa

6. The standard for the use of titanium bars in the chemical industry: GB/T2965-2010. ASTM B348. The standard for medical using: F67-2000 (Surgical implantation uses pure titanium.)

7. Titanium bar’s production process: preparing for blanks, heating, rolling, breaking off, rotary forging, annealing, heating, straightening, taking a sample, checking and storing.

2. The classification of titanium bar: the classifications of material for titanium alloy have grade TC4, TA9, TA10, TA18 and TC21. The classifications of shape have titanium round bar, titanium square rod, titanium square bar and titanium black bar.

3. The processing method of titanium bar: Hot rolled titanium bar. Hot extruded titanium bar. Hot forging titanium bar. All adopt the methods of scaling and polishing to process it into finished production.

4. The application of titanium bar: According to titanium bar’s characteristics of corrosion resistance, wear resistance, high temperature and no magnetic, etc. It is usually used as the main parts of the equipment, such as shaft, fasteners and stirring shaft, etc. Due to its non-toxic and non polluting characteristics, titanium bar is made into filter element and has a wide range of applications. In addition, titanium bars also have other characteristics such as high strength, good toughness, low elastic modulus and biocompatibility with human beings, which are widely used in medical industry.

5. Tensile strength of pure titanium: 250-320MPa. Tensile strength of titanium alloy: 890MPa

6. The standard for the use of titanium bars in the chemical industry: GB/T2965-2010. ASTM B348. The standard for medical using: F67-2000 (Surgical implantation uses pure titanium.)

7. Titanium bar’s production process: preparing for blanks, heating, rolling, breaking off, rotary forging, annealing, heating, straightening, taking a sample, checking and storing.

------分隔线----------------------------