Classification

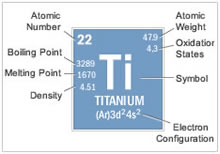

An introduction to the rolling technology of titanium alloy tube

Submitted by admin on 07/16/2015

It needs the second pass and third pass rolling to be rolled into a tube with 70% of total deformation. Between the passes, which needs the 800 ℃×1h vacuum annealing, and the different deformation amount is used to open the billet. The cooling method is that the furnace cooling to 500℃, and then air cooking to the room temperature, finally, you should observe its organizational performance changes.

The conclusion is that in the condition of the small deformation blooming, the wall thickness deviation is small, and the surface roughness degree will also gradually decreased; but the blooming with big deformation, the wall thickness deviation will big, which will affect the wall thickness deviation of the pipe from the subsequent rolling .

In the condition of the total deformation amount is the same, the rolling pass is more, the elongation and the hardness of the pipe is much greater, and the strength is higher. The comprehensive performance is good. The anisotropy of the tube has little effect on the condition of small deformation, and the anisotropy of the mechanical properties among the multi pass rolling has some fluctuation. When the rolling is with large deformation, the material flow appears the banded. On the contrary, the rolling with small deformation, the material flow will appear bundles. What's more, if the heat treatment conditions between the passes and the subsequent rolling process are same, the tissue distortion of tube obtained from the large amount of deformation on billet is more serious.

Zhengzhou Sanhui Co., Ltd has been dealing in refractory metals for 26 years. Which professionally manufacturer refractory and nonferrous metals, such as tungsten bar/rod/tube/pipe, molybdenum bar/rod/tube/pipe, and titanium alloy tubes and so on. Welcome to contact us earlier!

The conclusion is that in the condition of the small deformation blooming, the wall thickness deviation is small, and the surface roughness degree will also gradually decreased; but the blooming with big deformation, the wall thickness deviation will big, which will affect the wall thickness deviation of the pipe from the subsequent rolling .

In the condition of the total deformation amount is the same, the rolling pass is more, the elongation and the hardness of the pipe is much greater, and the strength is higher. The comprehensive performance is good. The anisotropy of the tube has little effect on the condition of small deformation, and the anisotropy of the mechanical properties among the multi pass rolling has some fluctuation. When the rolling is with large deformation, the material flow appears the banded. On the contrary, the rolling with small deformation, the material flow will appear bundles. What's more, if the heat treatment conditions between the passes and the subsequent rolling process are same, the tissue distortion of tube obtained from the large amount of deformation on billet is more serious.

Zhengzhou Sanhui Co., Ltd has been dealing in refractory metals for 26 years. Which professionally manufacturer refractory and nonferrous metals, such as tungsten bar/rod/tube/pipe, molybdenum bar/rod/tube/pipe, and titanium alloy tubes and so on. Welcome to contact us earlier!

------分隔线----------------------------