Classification

The properties of titanium

Submitted by admin on 11/13/2014

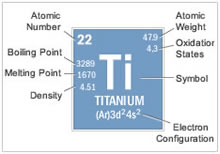

The density of titanium is 4.51g/ cm3, which is higher than aluminum, but less than steel, copper and nickel. However, the strength of titanium is in the first place among metals.

1. Corrosion resistance

Titanium is a very active metal, and its equilibrium potential is very low, the corrosion tendency of thermodynamics in the medium is high. But in fact, the titanium is very stable in many media, such as titanium is corrosion resistance in the media of oxidation, neutral and weak reducing medium. This is because the titanium and oxygen has a great affinity, in the air or oxygen containing medium, titanium surface will form a layer of oxide film that is dense, strong adhesion and inert. The oxide film will protect the titanium substrate from corrosion. Even if due to the mechanical wear, it also will quickly heal or regenerate. This indicates that the titanium has a strong deactivation tendency of metal. The Ti oxide film always maintain this characteristic when the medium temperature is below 15 ℃.

In order to improve the corrosion resistance of titanium, oxide, plasma spraying, electroplating, ion intruding, ion implantation and laser treatment and other surface treatment technology have been researched. They will have a function to increase the protection strengthen of titanium oxide films, and then titanium will achieve the desired corrosion effect. According to the need of metal material in sulfuric acid, hydrochloric acid, dim ethylamine solution, temperature of wet chlorine gas and temperature chloride in the production, the Ti Mo, Ti PD, Ti Mo Ni and a series of corrosion resistant titanium alloy has been developed. Titanium castings are made of the titanium -32 molybdenum alloy, local often on the crevice corrosion or pitting environment using -0.3 -0.8 titanium molybdenum nickel alloy or titanium equipment using titanium -0.2 palladium alloy, have received very good using effect.

2. Good heat resistance

A new type of titanium alloy can be used for a long time at 600℃ or higher temperature.

3. Good low temperature resistance

Titanium alloy TA7 (Ti-5Al-2.5Sn), TC4 (Ti-6Al-4V) and Ti-2.5Zr-1.5Mo as the representative of cryogenic titanium alloy, its strength increased along with the decrease of temperature, but the plastic property has hardly changed. Titanium can keep good ductility and toughness in the -196-253℃. Because it avoids the metal cold brittleness, it is the ideal material for cryogenic vessel, tank and other equipments.

4. Strong anti damping performance

After the titanium is affected by mechanical vibration and electric vibration, its vibration attenuation time is the longest compared with steel, copper metal. The properties of titanium can be used as a tuning fork, medical ultrasonic pulverizer vibrating element and high sound loudspeaker vibration film etc..

5. Non- magnetic and non-poisonous

Titanium is a non-magnetic metal, it will not be magnetized in a large magnetic field, non-toxic and good compatibility with human tissue and blood, so it is adapted by the medical community.

6. The similar tensile strength and yield strength

The performance of titanium shows its ratio of yield strength (tensile strength / yield strength) is high, and this also shows the plastic deformation of titanium material in forming is poor. The ratio of titanium yield limit and elastic modulus is large, and the rebound ability in titanium forming is strong.

7. Better heat transfer performance

Although the thermal conductivity of titanium is lower than carbon steel and copper, but because of the excellent corrosion resistance of titanium, so wall thickness can be greatly reduced, and the surface and the steam heat transfer mode is the dropwise condensation, titanium surface scaling can also reduce the resistance, so that the heat transfer performance of titanium significantly to be improved.

1. Corrosion resistance

Titanium is a very active metal, and its equilibrium potential is very low, the corrosion tendency of thermodynamics in the medium is high. But in fact, the titanium is very stable in many media, such as titanium is corrosion resistance in the media of oxidation, neutral and weak reducing medium. This is because the titanium and oxygen has a great affinity, in the air or oxygen containing medium, titanium surface will form a layer of oxide film that is dense, strong adhesion and inert. The oxide film will protect the titanium substrate from corrosion. Even if due to the mechanical wear, it also will quickly heal or regenerate. This indicates that the titanium has a strong deactivation tendency of metal. The Ti oxide film always maintain this characteristic when the medium temperature is below 15 ℃.

In order to improve the corrosion resistance of titanium, oxide, plasma spraying, electroplating, ion intruding, ion implantation and laser treatment and other surface treatment technology have been researched. They will have a function to increase the protection strengthen of titanium oxide films, and then titanium will achieve the desired corrosion effect. According to the need of metal material in sulfuric acid, hydrochloric acid, dim ethylamine solution, temperature of wet chlorine gas and temperature chloride in the production, the Ti Mo, Ti PD, Ti Mo Ni and a series of corrosion resistant titanium alloy has been developed. Titanium castings are made of the titanium -32 molybdenum alloy, local often on the crevice corrosion or pitting environment using -0.3 -0.8 titanium molybdenum nickel alloy or titanium equipment using titanium -0.2 palladium alloy, have received very good using effect.

2. Good heat resistance

A new type of titanium alloy can be used for a long time at 600℃ or higher temperature.

3. Good low temperature resistance

Titanium alloy TA7 (Ti-5Al-2.5Sn), TC4 (Ti-6Al-4V) and Ti-2.5Zr-1.5Mo as the representative of cryogenic titanium alloy, its strength increased along with the decrease of temperature, but the plastic property has hardly changed. Titanium can keep good ductility and toughness in the -196-253℃. Because it avoids the metal cold brittleness, it is the ideal material for cryogenic vessel, tank and other equipments.

4. Strong anti damping performance

After the titanium is affected by mechanical vibration and electric vibration, its vibration attenuation time is the longest compared with steel, copper metal. The properties of titanium can be used as a tuning fork, medical ultrasonic pulverizer vibrating element and high sound loudspeaker vibration film etc..

5. Non- magnetic and non-poisonous

Titanium is a non-magnetic metal, it will not be magnetized in a large magnetic field, non-toxic and good compatibility with human tissue and blood, so it is adapted by the medical community.

6. The similar tensile strength and yield strength

The performance of titanium shows its ratio of yield strength (tensile strength / yield strength) is high, and this also shows the plastic deformation of titanium material in forming is poor. The ratio of titanium yield limit and elastic modulus is large, and the rebound ability in titanium forming is strong.

7. Better heat transfer performance

Although the thermal conductivity of titanium is lower than carbon steel and copper, but because of the excellent corrosion resistance of titanium, so wall thickness can be greatly reduced, and the surface and the steam heat transfer mode is the dropwise condensation, titanium surface scaling can also reduce the resistance, so that the heat transfer performance of titanium significantly to be improved.

------分隔线----------------------------